Omniscope

Omniscope is a powerful solution designed for analyzing plastic and foam materials, providing real-time insights into their internal structure. Both the Omniscope Platform and Omniscope Lab use advanced vision systems to capture high-resolution images of material cross-sections, allowing for precise measurement of cell sizes, distribution, and other key performance indicators.

Whether used in production environments or research and development, Omniscope enables users to monitor and optimize material quality with accurate, repeatable data, ensuring better control over manufacturing processes and enhanced product performance.

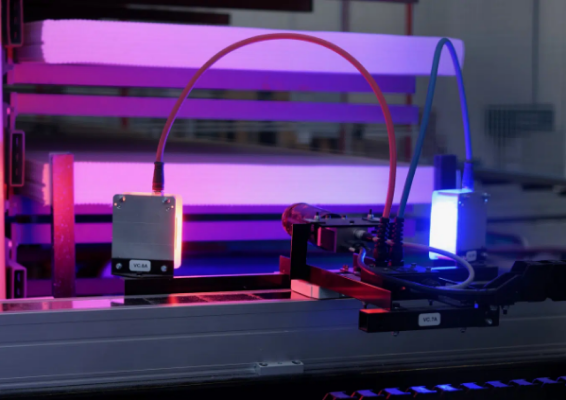

Omniscope In-line Platform

Integrated Real-Time Plastic Production Control and Monitoring

The Omniscope Platform provides a comprehensive KPI measurement solution tailored for in-line plastic and foam production. The Omniscope Platform captures critical data in real time, empowering manufacturers and production teams to optimize processes, improve efficiency, and ensure consistent material quality throughout continuous production.

Omniscope Lab

Analysis tool for R&D purposes

The Omniscope provides a comprehensive KPI measurement solution tailored for in-line plastic production. The Omniscope Platform captures critical data in real time, empowering users to make informed decisions to optimize production processes efficiently.

A quality control process revolution

A leading manufacturer of core material came to Omniscope with the ambition to perform in-line quality control. With the Omniscope in-line System solution in place, the manufacturer moved from measuring 1 sample out of 10 000, to measuring all produced PET boards.

They also got access to the quality data needed to optimize their process control, reduce their costs and wastes, and improve the quality of their final product.

"It would be an understatement to say that Omniscope have delivered value for us, they have revolutionized our whole quality control process. "

Omniscope

In-line

Platform

How it works

Input

Plastic patterns and structure

Different plastic materials with varied structures, patterns, and colors.

Image capturing

Cross section image of the material is taken by a custom-built vision system.

Omniscope Platform solution

Valuable KPI data is extracted, in real-time.

Output

Key performance indicator data

KPI data such as cell distribution, coalescence, and avg. cell diameter is presented through an interactive interface.

Value creation

• Repeatable in-line quality measures

• Quality trends in real-time

• Identified defects Improved yield

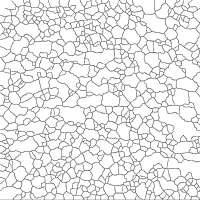

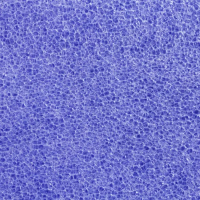

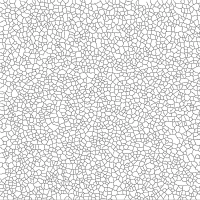

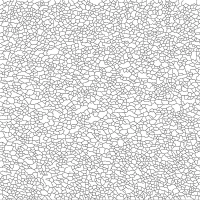

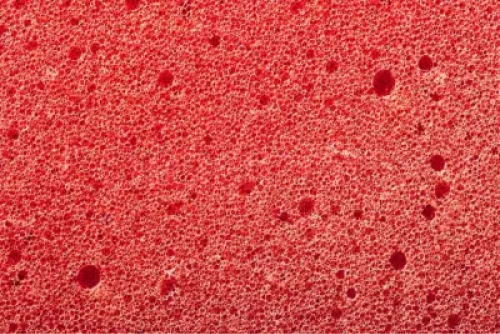

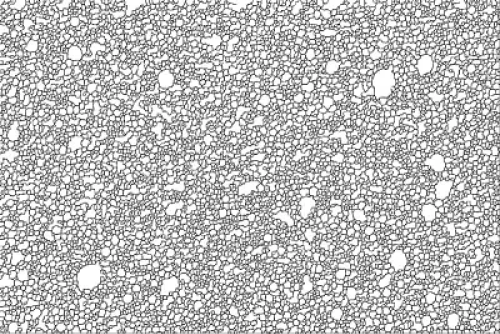

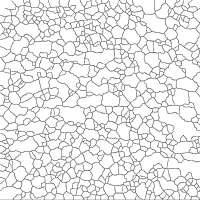

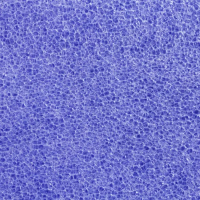

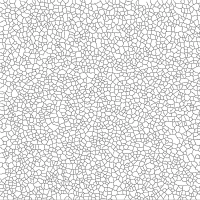

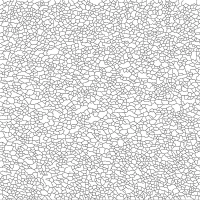

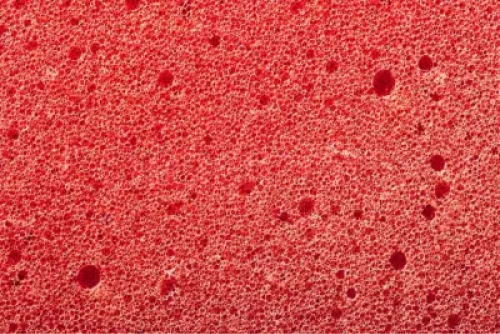

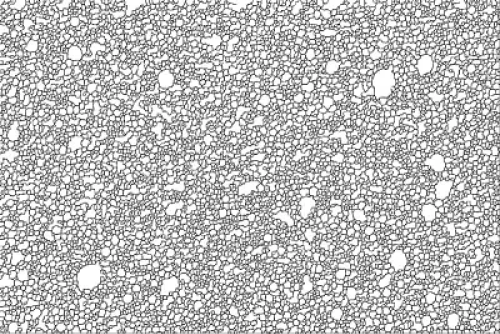

Unprocessed and processed images

PP plastic

EPE foam

PET plastic

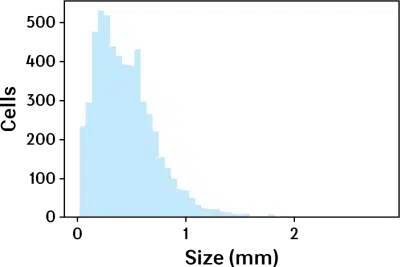

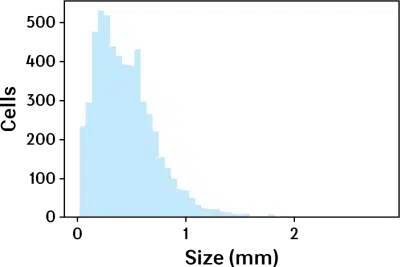

Analysys and KPI of material

Polyurethane foam

Processed image

Processed image

Capabilities

- Average cell size

- Pinholes

- Cell size distribution

- Coalescence index

With the web-based visualization tool the user can view real-time data and follow quality trends for manufactured plastic.

Manual methods, such as resin or water uptake tests, for testing the quality of a product can be replaced by our vision system.

All data will be stored in a database which can be used for further analysis to gain production process insights.

Technical data

Scanning information

Scanning speed

150 mm / 1 sec

Default scanning capability

1200 mm x 80 mm

*The area’s maximum and minimum scan sizes depend on the request and are adjustable.

Dimensions

Omniscope vision stand

600* x 650 x 1300* mm

*Default sizes. Customizable according to customer requirements

Camera

Working distance

314 mm ± 1 mm

Resolution

4500 x 4500 pixels

Cell diameter resolution

100 μm

System

Power supply

100–240 V, 50–60 Hz, 950 W

Communication

- TCP/IP

- Software and data storage on customer server

- WebApp data visualization (additional)

- SPC compatible

Real-time KPI calculations

Yes

Atmospheric sensor

Temperature, humidity and atm. pressure – AtmoBox (additional)

Omniscope

Lab

How it works

Input

Material samples

Different plastic materials with varied structures, patterns and colors.

Image capturing

Positioning of specimen with a live placement preview.

Omniscope Lab Platform solution

Valuable KPI data is extracted in less than a minute.

When the scan is completed the results will automatically be presented.

Output

Key performance indicator data

KPI data such as cell distribution, coalescence, and avg. cell diameter is presented through an interactive interface.

Value creation

• Repeatable quality assurance measures

• Quick quality feedback for R&D

• Better material understanding

Unprocessed and processed images

PP plastic

EPE foam

PET plastic

Analysis and KPI of material

Polyurethane foam

Processed image

Processed image

Capabilities

- Average cell size

- Cell size distribution

- Coalescence index

Manual methods, such as resin or water uptake tests, for testing the quality of a product can be replaced by our vision system.

All data will be stored in a database which can be used for further analysis to gain production process insights.

Technical data

General

Weight

8 kg

Dimensions

420 x 200 x 320 mm

Input devices

Software on customer PC

Camera

Scan area per shot

50 x 50 mm

Resolution

4500 x 4500 pixels

Cell diameter resolution

80 μm

System

Power Supply

100–240 V, 50–60 Hz, 150 W

Communication

- Software and data storage in customer PC

- WebApp data visualization*

- SPC compatible

Real-time KPI calculations

Yes